超声波线束焊接 has the following advantages:

1. High welding quality – Firm connection: Through high-frequency vibration, the surface molecules of the wire harness penetrate and blend with each other, forming a firm metallic bond connection. The welding points have high strength and can withstand large tensile forces and currents. – Good stability: The welding parameters are easy to control, and the repeatability is strong, which can ensure the consistency of the welding quality each time and reduce the defective product rate. – Little damage to the wire: Relatively little heat is generated during the welding process, and the heat-affected zone is small. It can effectively prevent problems such as the aging and embrittlement of the insulating layer and the deterioration of the wire performance caused by overheating of the wire harness, and maintain the original performance of the wire harness.

2. High production efficiency – Fast welding speed: Ultrasonic welding is a rapid welding process. Each welding only takes a fraction of a second to a few seconds, and automated continuous production can be achieved, greatly improving production efficiency. – No need for auxiliary materials: Unlike some traditional welding methods that require welding rods, fluxes and other auxiliary materials, it saves the time and cost of adding auxiliary materials, and avoids problems such as impurity contamination caused by auxiliary materials.

3. Environmental protection and energy saving – No pollutant emissions: During the welding process, no pollutants such as smoke, exhaust gas, and waste residues are generated, which is friendly to the environment and meets environmental protection requirements. – Low energy consumption: The power of ultrasonic welding equipment is relatively low, and energy is only consumed during welding. Compared with some high-energy-consuming welding technologies, such as arc welding, it can effectively save energy.

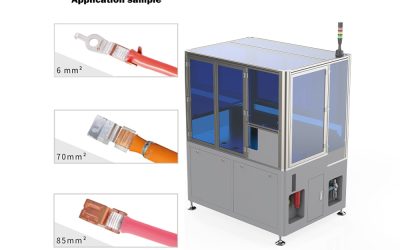

4. Wide range of applications – Can weld a variety of materials: It can weld various metal wire harnesses, including copper, aluminum and their alloys, etc., and can also be used for the welding of wire harnesses made of different metal materials, such as the welding of copper-aluminum wire harnesses. – Suitable for a variety of wire harness specifications: Whether it is a tiny wire harness as thin as a hair or a thicker multi-strand wire harness, ultrasonic welding can adapt well, and the welding parameters can be adjusted according to the specifications of the wire harness.

5. High safety – Non-contact welding: Ultrasonic welding transfers the vibration energy to the wire harness for welding through the welding head without direct contact with the wire harness, reducing the risk of operators being scalded due to contact with high-temperature welding components. – No electric shock risk: The voltage of the equipment during operation is relatively low, and good insulation and grounding measures are adopted, effectively reducing the possibility of electric shock for operators.

If you have any questions, you are welcome to contact us at any time.CONTACT US

EMAlL:delin@himinsens.com

TEL+8618938694287

ADDRESS: 101, BUILDING 8, JIN’AN BUILDING, SHANGCUN, GONGMING

STREET, GUANGMINGDISTRICT, SHENZHEN, GUANGDONG, CHINA

0条评论