I. Generation of ultrasonic waves Ultrasonic generator:

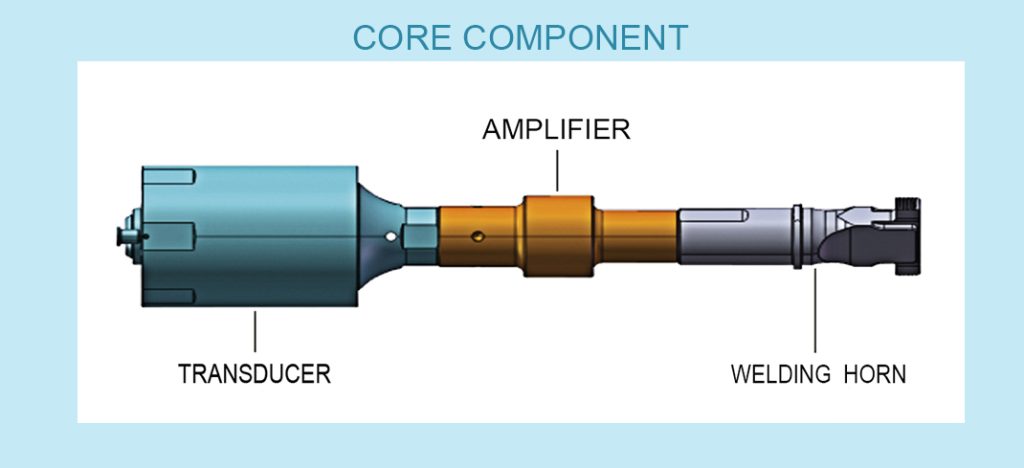

It converts ordinary power sources (such as mains power) into high-frequency electrical energy signals. The frequency usually ranges from 15 kHz to 60 kHz. This high-frequency electrical energy signal is the energy source for the subsequent welding process. Transducer: The high-frequency electrical energy signal acts on the transducer (usually made of piezoelectric ceramic materials). Utilizing the piezoelectric effect, the transducer converts electrical energy into mechanical vibration energy of the same frequency, generating high-frequency mechanical vibrations.

II. Vibration transmission and welding process Amplitude modulator:

The mechanical vibration output from the transducer is amplified in amplitude by the amplitude modulator. The function of the amplitude modulator is to adjust and optimize the amplitude of the vibration to meet different welding requirements. Welding tip: The amplified mechanical vibration is transmitted to the welding tip.

The welding tip:It is usually made of high-strength and high-fatigue-resistant materials such as titanium alloy and is in direct contact with the wire harness to be welded. Wire harness contact and friction: When the welding tip contacts the wire harness, the high-frequency vibration causes a high-frequency relative frictional movement between the wire harnesses. During the friction process, the oxide film and impurities on the surface of the wire harness are removed, exposing a pure metal surface.

0条评论