Are you troubled by poor welding quality?

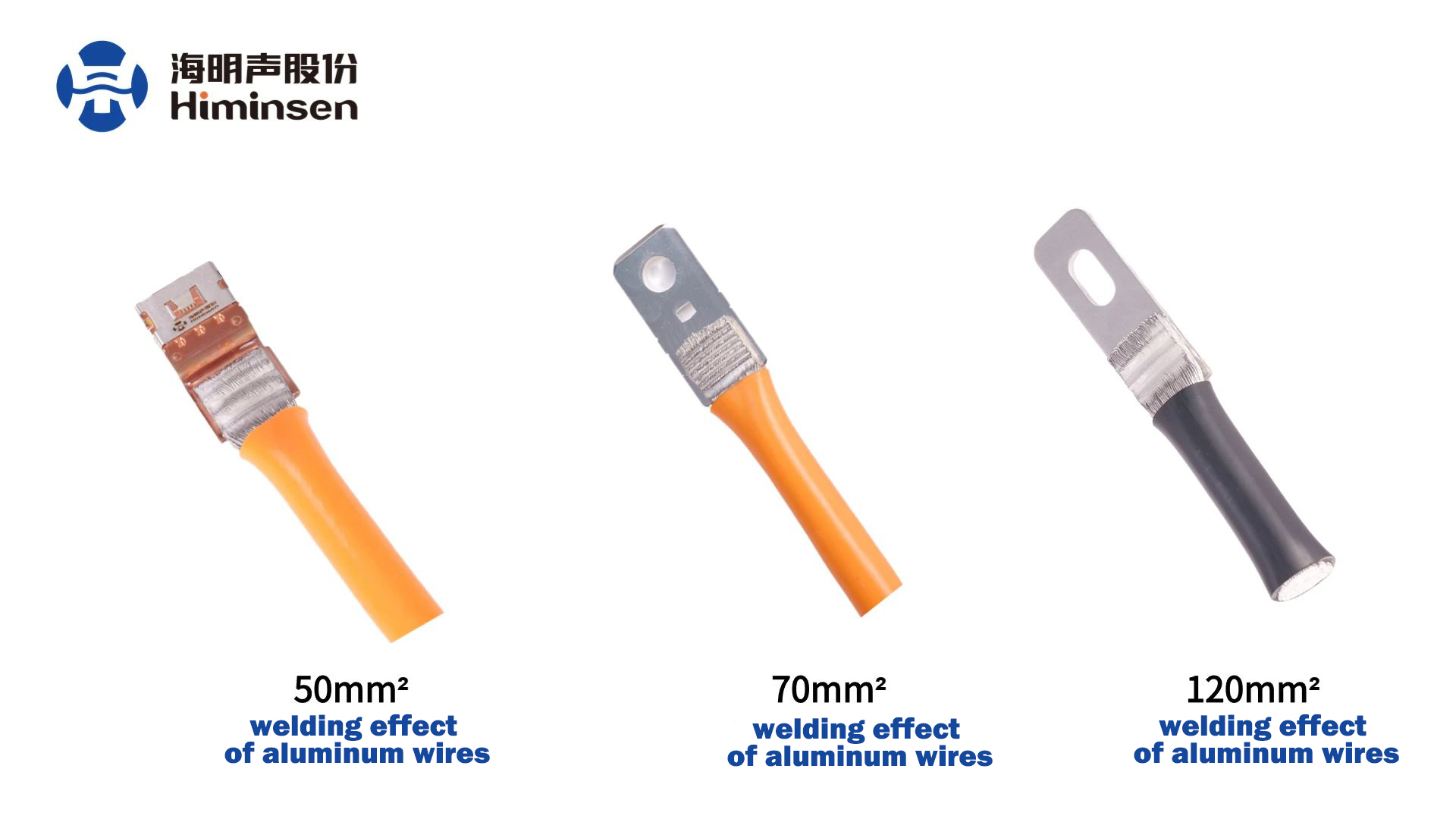

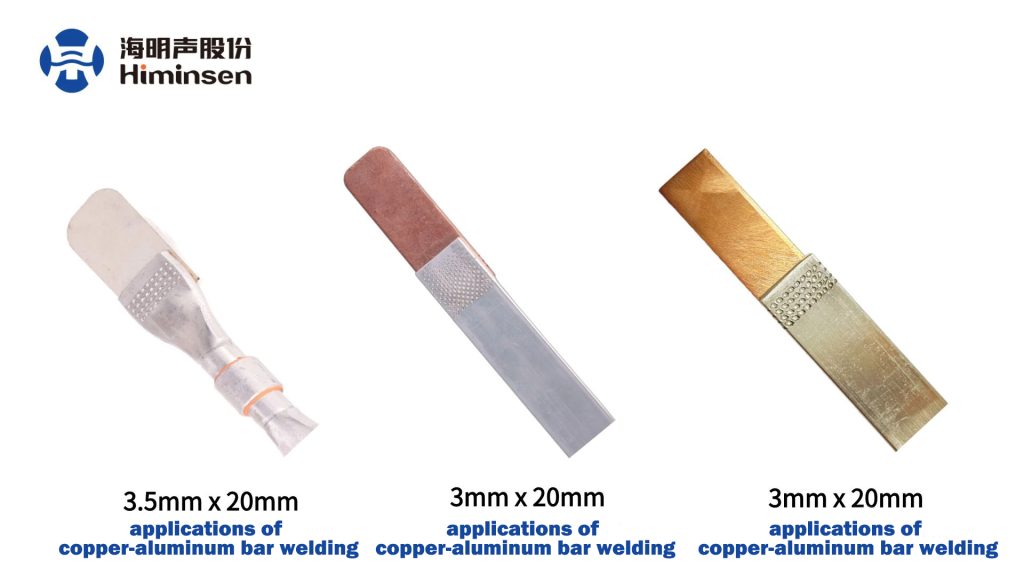

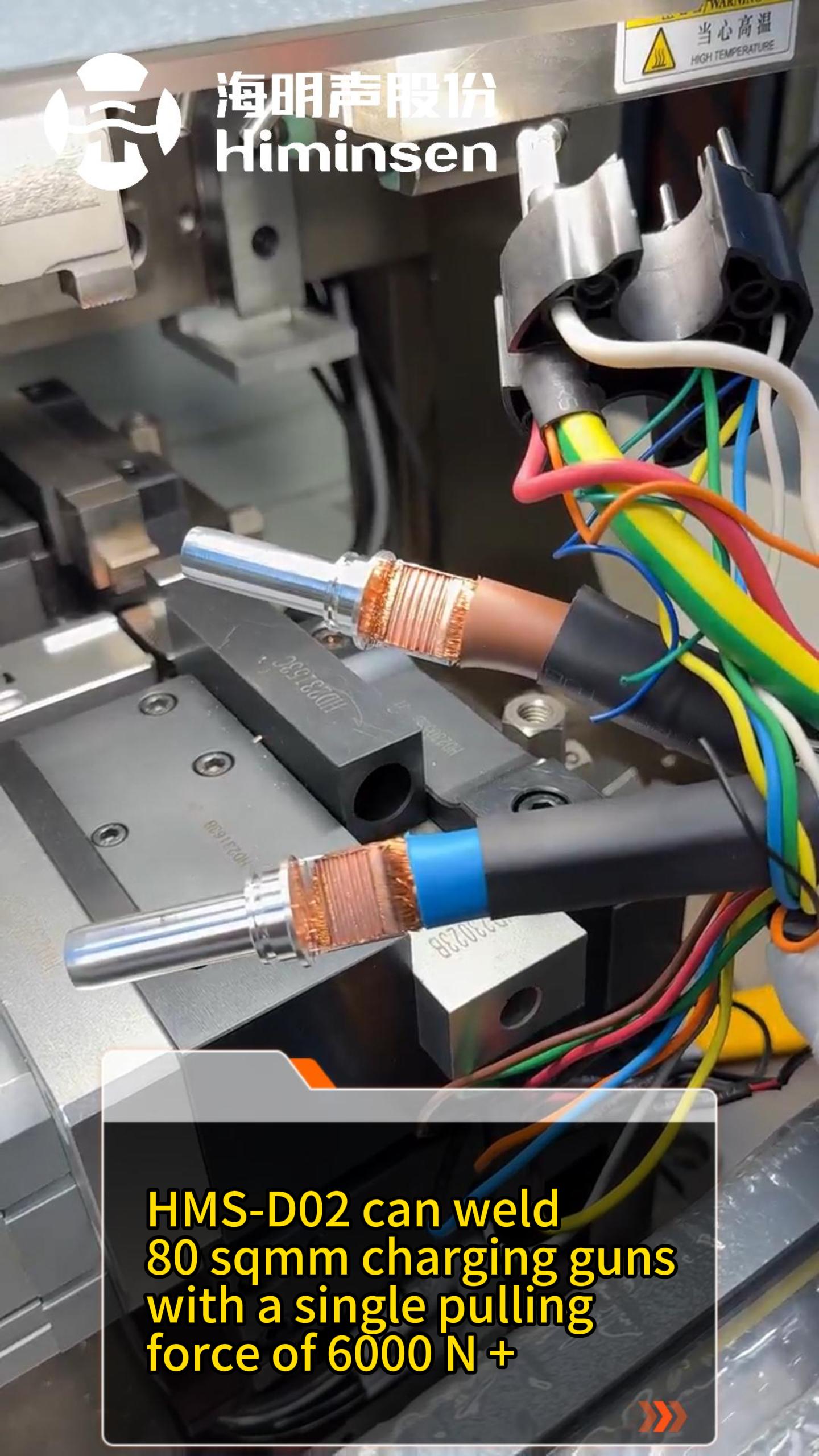

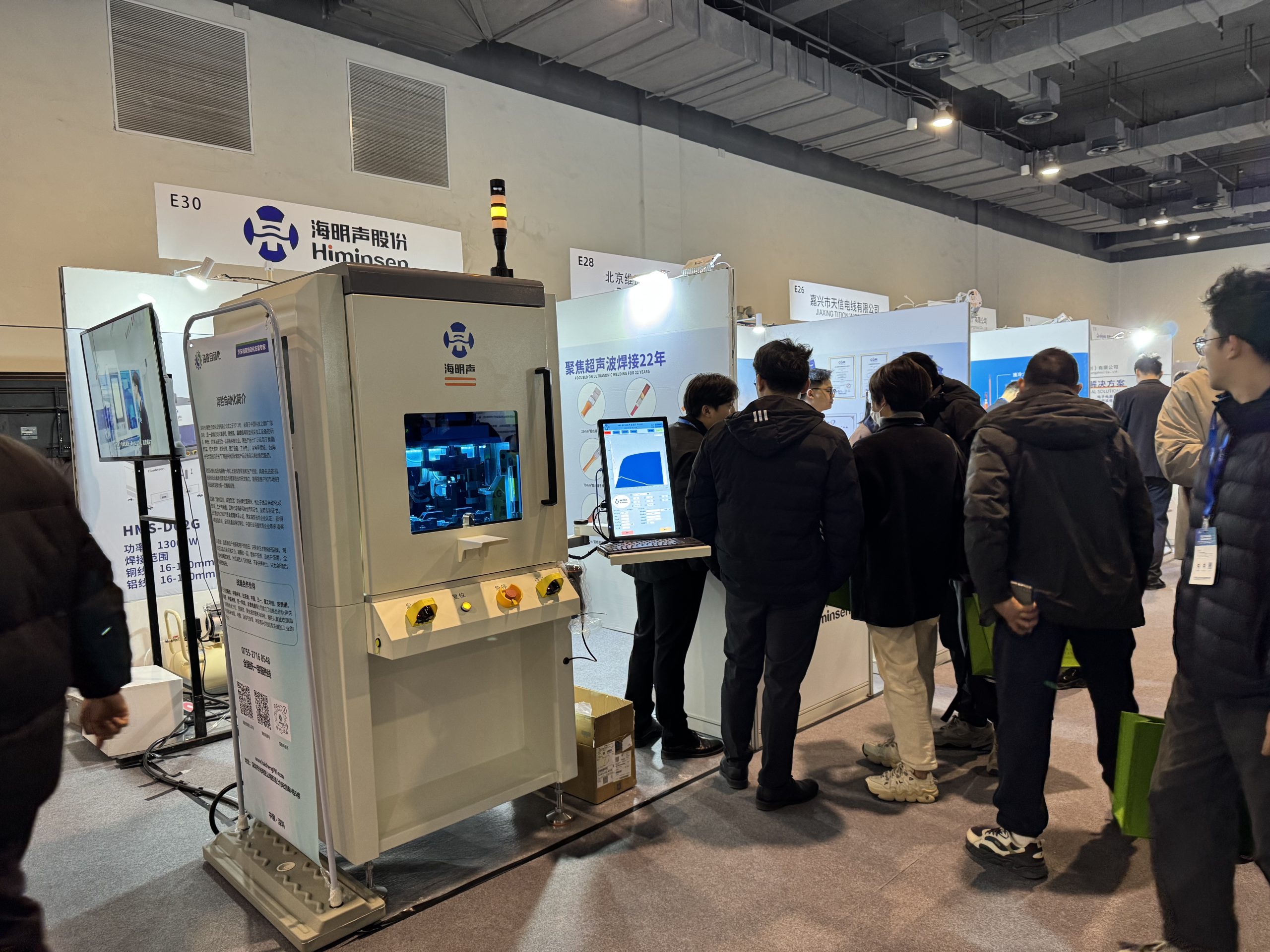

Do you long to find an efficient and reliable welding method? Today, we will introduce the Himinsen ultrasonic terminal welding machine to you. It will solve your welding problems and provide excellent welding quality! With its mature ultrasonic metal welding technology, Himinsen has provided efficient and modern ultrasonic terminal welding solutions for new energy vehicle wire harness manufacturers and has become a leader in the welding field. This technology can help weld metal materials of different materials, such as copper, aluminum, nickel or other non-ferrous metals. Ultrasonic metal welding is an industrial process of high-frequency ultrasonic vibration. That is to say, pressure is applied between components, and through high-frequency vibration and friction, solid-state welding is formed. This welding technology has the following remarkable advantages:

1. High-quality welding: The ultrasonic welding of Himinsen can provide firm and aesthetically pleasing weld seams with high welding strength.

2. Efficient production: Compared with traditional crimping methods, ultrasonic welding is faster and greatly improves production efficiency.

3. Wide applicability: It is applicable to a variety of metal materials, including non-ferrous metal materials such as aluminum, brass, bronze, red copper, nickel in the form of thin wires or sheets.

4. Environmentally friendly and energy-efficient: There are no sparks or welding spatter during the ultrasonic welding process, reducing environmental pollution. The ultrasonic welding equipment has low energy consumption, requiring only 10% of the energy consumption of resistance welding, thus saving energy.

5. Good electrical conductivity: The resistance coefficient of the welded joints is extremely low or nearly zero after welding, with excellent electrical conductivity.

6. Excellent process control: By using electronic process control and digital traceability of welding parameters, it can comprehensively control all parameters in the welding process and ensure that each welding meets industry standards and quality requirements.

0条评论