With the rapid advancement of technology, industrial welding techniques are constantly evolving. Among them, ultrasonic wire harness welding has become a favorite in numerous industries, quietly revolutionizing traditional welding methods with its unique advantages. Today, let’s take an in-depth look at this cutting-edge technology and discover what makes it truly remarkable!

I. The Core Advantages of Ultrasonic Wire Harness Welding

1. Efficient Welding: Time and Labor Saving

Traditional welding methods often require long waiting times. In contrast, ultrasonic wire harness welding utilizes the frictional heat generated instantaneously by high-frequency vibrations to complete the welding process in an extremely short time. Take automotive wire harness production as an example. After adopting ultrasonic welding technology, the welding time for a single wire harness can be reduced to 0.5 – 1 second, significantly improving production efficiency and saving substantial time and labor costs for enterprises.

2. Robust and Reliable: Superior Quality

Ultrasonic welding enables the mutual penetration of metal surface molecules through high-frequency vibrations, forming a firm metallurgical bond. This welding method eliminates the need for soldering flux, avoiding issues such as cold soldering and desoldering. The welded joints feature high strength and excellent electrical conductivity, ensuring the stability and reliability of wire harness connections even in harsh environments. Tests have shown that the tensile strength of ultrasonic-welded wire harness joints is 30% higher than that of traditional welding methods.

3. Green and Environmentally Friendly: Safe and Healthy

In an era of growing environmental awareness, the green characteristics of ultrasonic wire harness welding stand out. It generates no smoke, exhaust gases, or waste residues, and does not require chemical solvents, reducing environmental pollution and minimizing harm to operators’ health. It fully aligns with the concept of sustainable development, making it a truly “green welding” technology.

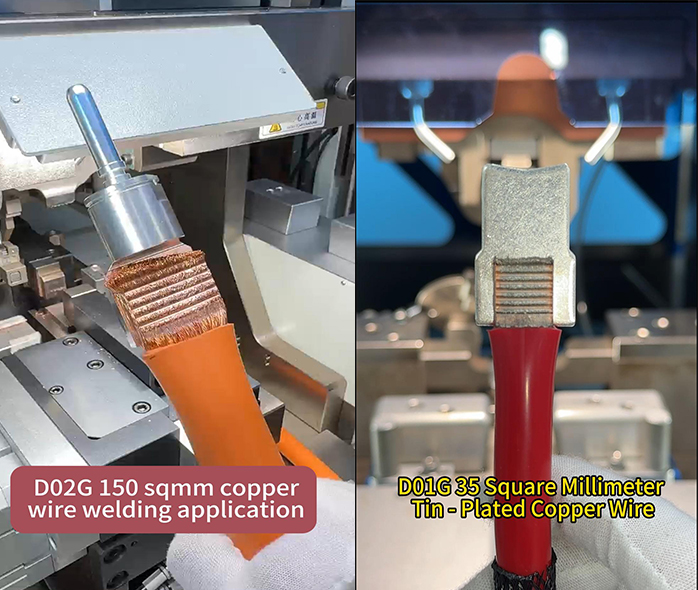

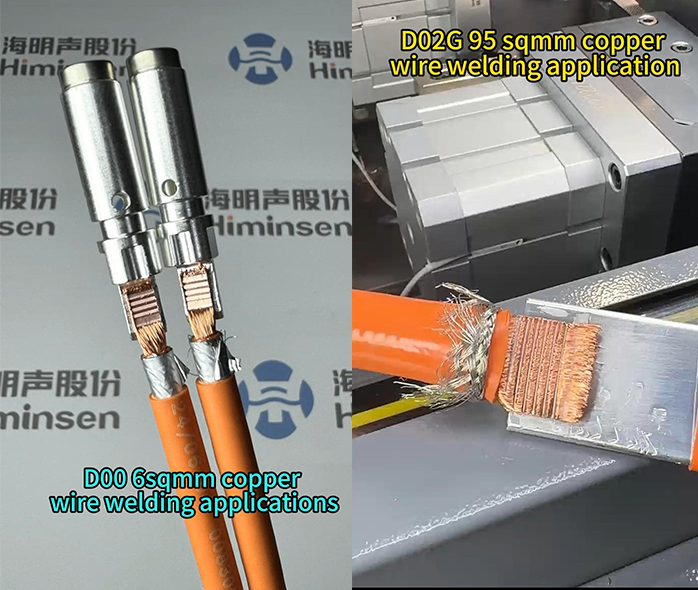

4. Precise Control: Wide Applicability

Ultrasonic welding equipment can precisely adjust welding parameters according to different wire harness materials, specifications, and welding requirements, enabling customized welding. Whether it’s tiny electronic wire harnesses or large automotive wire harnesses, it can handle them with ease. Moreover, the welding process is stable and consistent, effectively reducing the defect rate.

If you need to inquire about more detailed information, please contact the contact details below.

CONTACT US

EMAlL:delin@himinsens.com

TEL+8618938694287

ADDRESS: 101, BUILDING 8, JIN’AN BUILDING, SHANGCUN, GONGMING

STREET, GUANGMINGDISTRICT, SHENZHEN, GUANGDONG, CHINA

全天候在线聊天

全球客户服务中心,24小时在线为您提供售前售后咨询服务。

快速交货

全面的供应链管理系统、产品智能生产系统和质量管控系统确保30天内快速交货。

安全支付

我们支持T/T付款,也支持阿里巴巴等国际第三方担保平台支付。我们承诺在收货后7天内退换货,让您买得放心,用得舒心。

你的需求,我们的动力!

品质决定生存

服务决定价值!

CEO杨丰铭