With the rapid development of the automotive electronics and new energy industries, the quality and efficiency of wire harness welding have become crucial for enterprise competition. Traditional welding processes often suffer from problems such as poor soldering, oxidation, and deformation, which not only affect product performance but also increase costs and delivery cycles. Himinsen, with its cutting – edge ultrasonic wire harness welding technology, provides efficient sampling services for numerous enterprises, successfully tackling industry challenges!

Case : Welding of Core Components in New Energy Vehicles

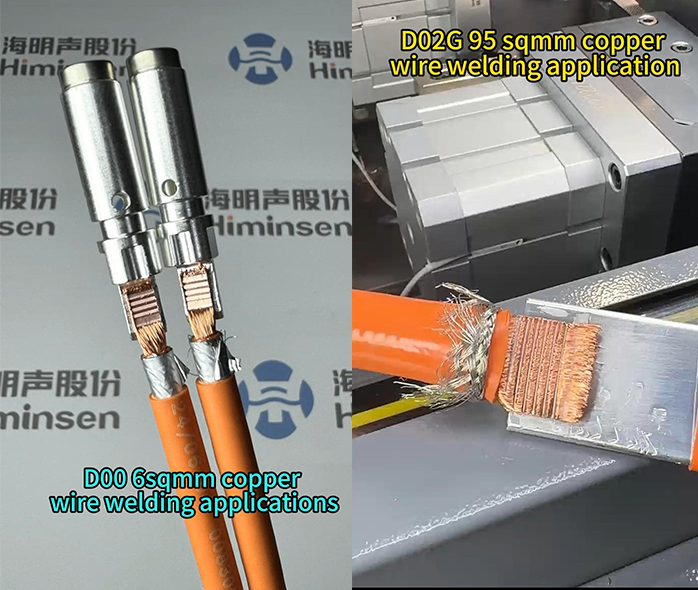

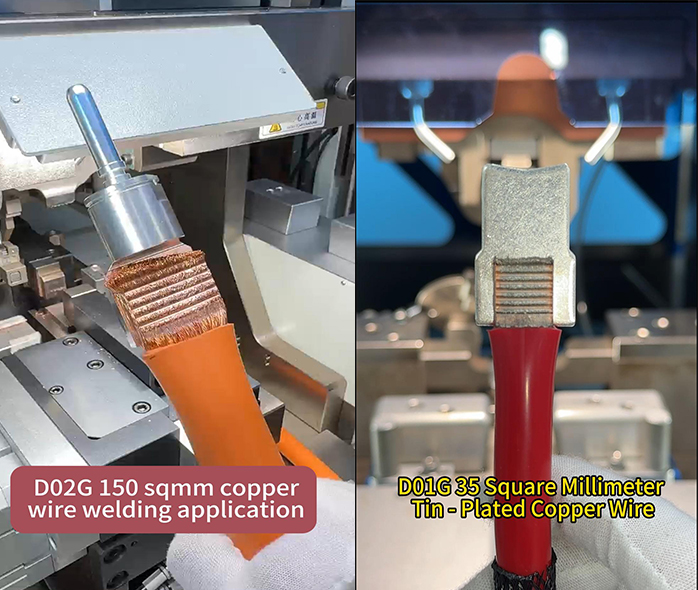

When a leading new energy vehicle manufacturer was developing a new – generation battery management system, it needed to weld multiple copper wires of different specifications to precision terminals. Traditional welding methods caused wire fusing and terminal deformation, failing to meet safety standards. Our team conducted in – depth analysis of the product requirements and used Himinsen’s customized ultrasonic wire harness welding equipment

If you need to inquire about more detailed information, please contact the contact details below.

CONTACT US

EMAlL:delin@himinsens.com

TEL+8618938694287

ADDRESS: 101, BUILDING 8, JIN’AN BUILDING, SHANGCUN, GONGMING

STREET, GUANGMINGDISTRICT, SHENZHEN, GUANGDONG, CHINA

全天候在线聊天

全球客户服务中心,24小时在线为您提供售前售后咨询服务。

快速交货

全面的供应链管理系统、产品智能生产系统和质量管控系统确保30天内快速交货。

安全支付

我们支持T/T付款,也支持阿里巴巴等国际第三方担保平台支付。我们承诺在收货后7天内退换货,让您买得放心,用得舒心。

你的需求,我们的动力!

品质决定生存

服务决定价值!

CEO杨丰铭