- Transverse Die

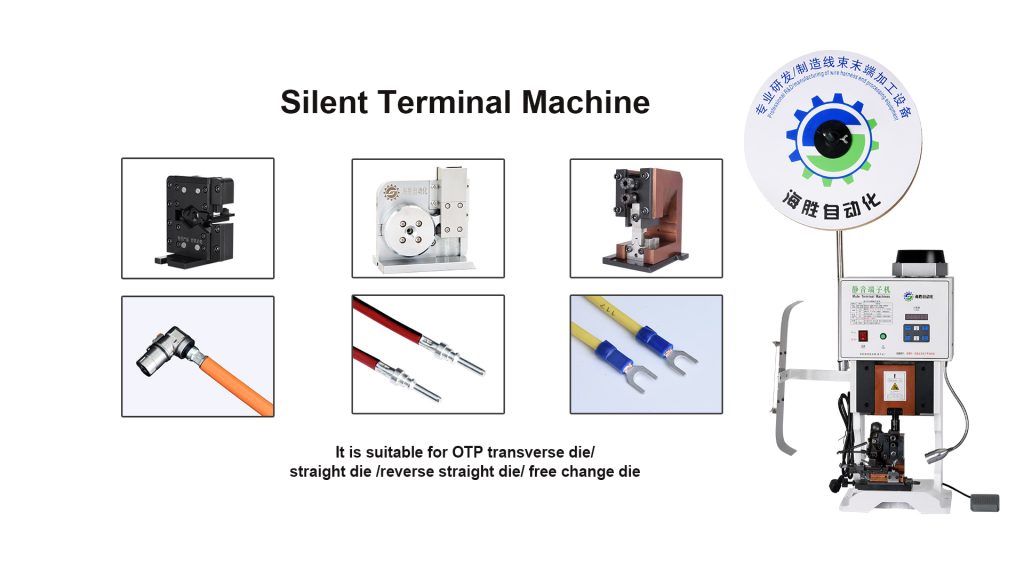

Mold installation direction: On the terminal crimping machine, the horizontal mold is installed along the direction parallel to the operating plane of the equipment.

Crimping action: Its crimping action mainly extrudes the terminals and wires in the horizontal direction to form a connection between the terminals and wires. From the perspective of the mechanical structure, the movement trajectory of the internal crimping components is a horizontal linear or curved motion. - Straight Die

Mold installation direction: The vertical mold is installed in the direction perpendicular to the operating plane of the terminal crimping machine.

Crimping action: The crimping action is carried out in the vertical direction, applying pressure on the terminals and wires from top to bottom or from bottom to top. The internal crimping components complete the crimping operation by moving linearly in the vertical direction. - Reverse Straight Die

Mold adjustment method: The diewithout replacement has an adjustable structure in design. It can adapt to the crimping of terminals of different specifications without replacing the entire mold. It may change the size and shape of the crimping by adjusting some movable parts on the mold, such as movable crimping blocks and adjustable spacing devices.

Mold universality: This kind of mold has high universality and can be compatible with multiple terminals of different models and sizes within a certain range. For example, by adjusting some parameters on the mold, it can perform crimping operations on wires of different diameters and terminals of different shapes.

0 Comments