UlTRASONIC AC 380V 50HZ

TERMINAL WELDING MACHINE

Efficient welding

TERMINAL WELDING MACHINE

About 1~3 s/time, depending on the welding square

Product Introduction

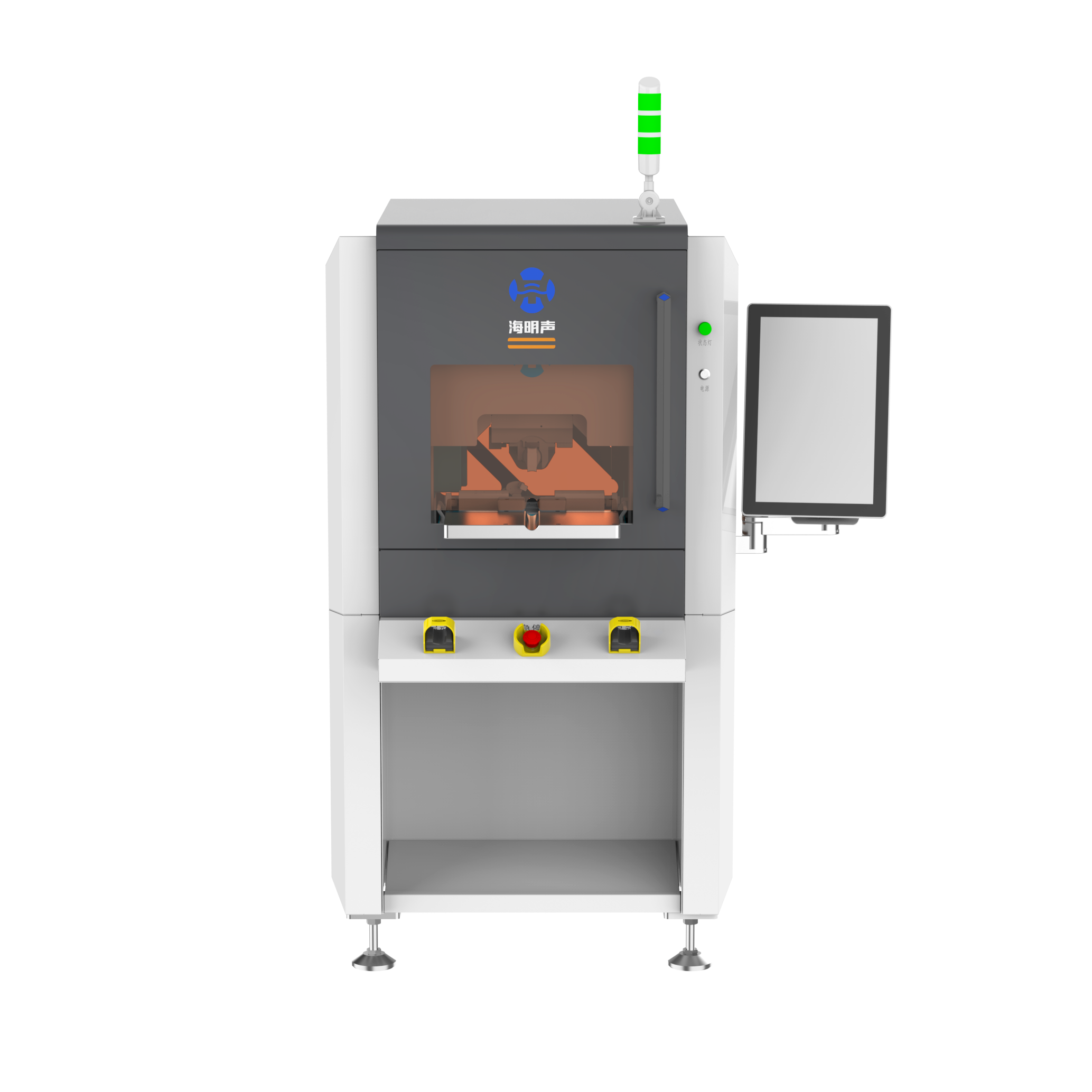

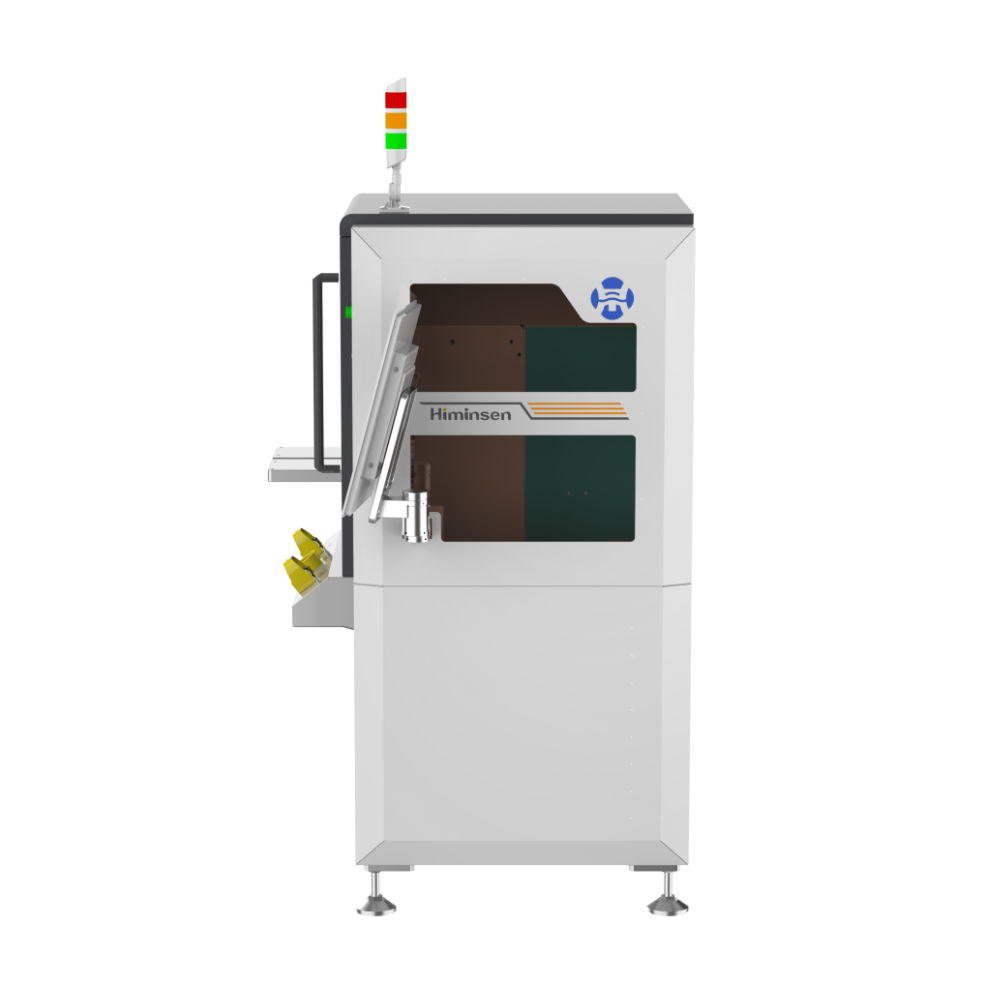

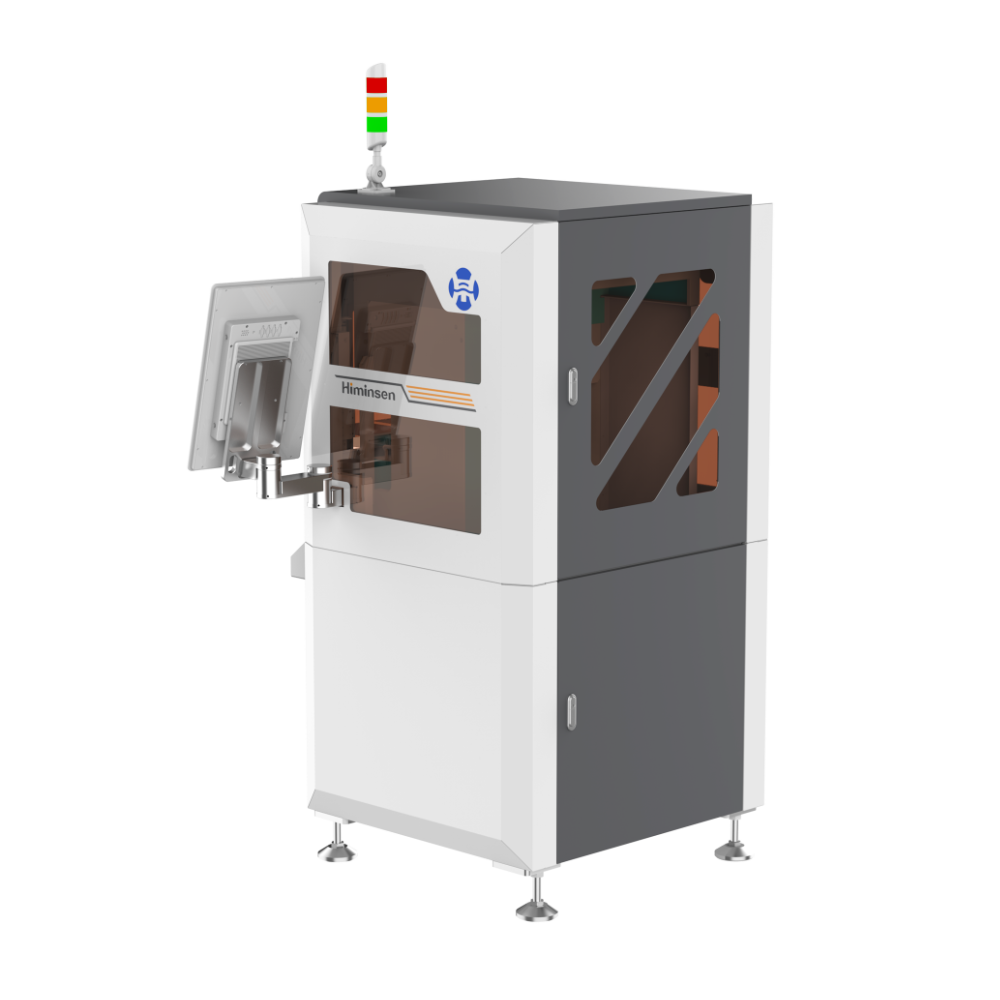

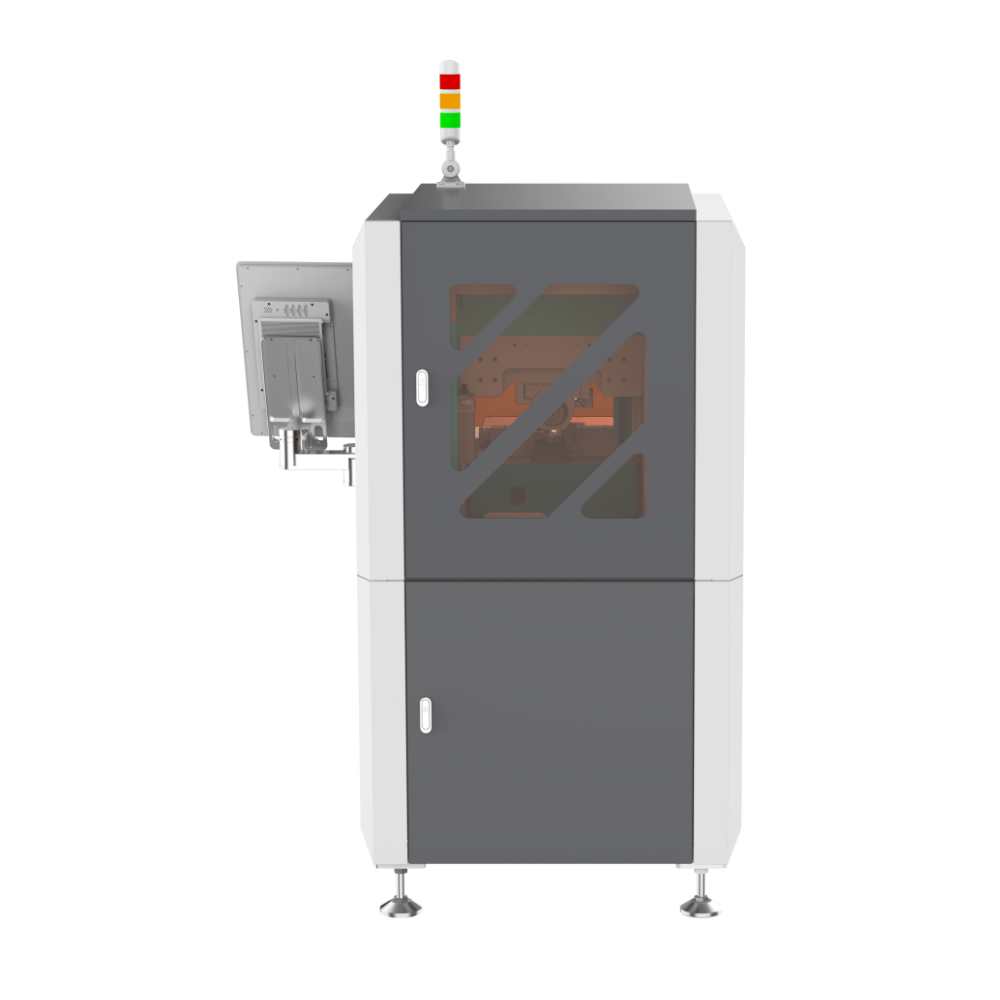

HMS-D01G Ultrasonic Terminal Welding Machine

Warning Light

10.1 Inch Touch Screen

Electrical Box

Welding Structure

Action Buttons

The HMS-D01G ultrasonic terminal welding machine provides an introductory ultrasonic-level welding experience for all types of customers. It is a user-friendly and low-maintenance ultrasonic welding solution for many markets with the lowest machine cost.

The machine's welding capabilities cover a wide range of cross-sectional dimensions from 2.5 mm² to 25 mm². In addition, it offers many benefits over traditional welding methods.

This ultrasonic terminal welding machine is a one-step welding machine for copper wire connection, which can be welded once in 1~3 seconds. No heating is required, and no consumables or connectors are required.

| Model | D01G |

| Power | 9000W |

| Copper wire welding range | 6mm² -95mm² |

| Aluminum wire welding range | 6mm² -95mm² |

| Configuration | Himinsen |

| Input Voltage | AC 380V(-10/+60) 50~60Hz |

| Size | 1300*1000*2000mm |

| Weight | 610kg |

| Air Pressure | >0.5MPa |

| Data Storage | 100.000 sets of product welding parameters |

| Product Efficiency | 120pcs/H—150pcs/H |

| Alarm | Control the welding time, energy, pressure, amplitude power, pre-weld height, and post-weld height |

| Interface Display | It can display welding time, energy, power, pressure, times, amplitude, frequency and other information |

| Display Method | 18.5inch touch all-in-one computer |

| HS Code | 8515809090 |

| Application | Vehicles, instruments and meters, communication equipment, household appliances, etc. |

Product Advantages

No Additional Material Required

No flux, flux or other filler materials are required during ultrasonic soldering, reducing material costs and the risk of environmental contamination.

Low Temperature Welding

The temperature generated during the welding process is low, only equivalent to 1/3 or 1/2 of the melting point of the metal, which means the welding process will not cause damage to the insulation of the wire and retain the original properties of the metal wire. Low-temperature welding also allows thin metals to be welded to thick metals without causing damage to them.

Energy Saving And Environmental Protection

Compared with traditional welding methods (such as crimping, soldering, and resistance welding), ultrasonic welding has low energy consumption and does not require an external heating source, reducing energy consumption and carbon emissions.

Advanced Process Control

Equipped with a touchscreen controller, it displays and monitors ultrasonic welding parameters (such as amplitude, pressure, time, etc.) in real-time to ensure precise control of the welding process, so as to achieve the highest standard of welding quality.

Compact And Portable

The device is small in size and light in weight, making it easy to operate and store in a limited space.

Constant Welding Quality

The integrated system ensures the stability of welding parameters, avoids quality fluctuations caused by human factors, and ensures welding consistency, especially suitable for mass production needs.

Safety And Ease Of Use

It has the function of automatic frequency tracking and calibration, the maintenance, operation, and tool replacement of the equipment are simple, fast, and safe, and the structural design is simple and precise, which improves the safety and work efficiency of operators.

Strong Adaptability

It is not only suitable for welding between similar metals (such as copper and copper, aluminum and aluminum), but also can realize the welding of different metals (such as copper and aluminum), and the large welding cross-section range (from 0.35 square millimeters to 200 square millimeters) can adapt to the needs of a variety of wiring harness specifications. Expanded range of applications.

Efficient And Fast

The welding process only takes 1-2 seconds, which greatly improves the production efficiency and meets the needs of large-scale production. At the same time, the welded workpiece does not need to be cooled or pressured for a long time, saving the production cycle.

High Welding Strength

Because the joint formed by ultrasonic welding is metallurgically combined, its strength often exceeds that of the base metal, and there is no obvious welding slag and burr in the welding area, and the appearance is smooth, which is conducive to the subsequent assembly and optimization of electrical properties.

Password Protection And Parameter Storage

Ability to store the welding parameters of each size of wire as a template. Avoid changing different specifications of threads each time and need to manually reset different parameters, which can greatly provide the stability of work efficiency and product quality.

Prevent Empty Welding

Prevent damage to parts such as left and right sliders, horn, and Cushion Block.

Product Comparison

HMS-D00

- 2.5mm² ~ 25mm²

- AC 220V 50Hz

- 640*425*330mm

- 220 kg

- 20KHz

- 10.1-inch touch screen

- About 1~3 s/time, depending on the welding square

HMS-D01G

- 6mm² ~ 95mm²

- AC 380V 50Hz

- 1300*1000*2000mm

- 610kg

- 20KHz

- 18.5 inch touch screen

- About 1~3 s/time, depending on the welding square

HMS-D02G

- 16mm² ~ 120mm²

- AC 380V 50Hz

- 2060*1650*1300mm

- 944kg

- 20KHz

- 21.5 inch touch screen

- About 1~3 s/time, depending on the welding square

Additional information

| Power | 5000W |

|---|---|

| Weight | |

| Input Voltage | AC 220V 50Hz |

| HS Code | 8515809090 |

24/7 Live Chat

Global customer service center, 24 hours online to provide you with pre-sales and after-sales consulting services.

Fast Delivery

A comprehensive supply chain management system, smart production system for products, and quality control management system ensure rapid delivery within 30 days.

Secure Checkout

We support T/T and also support international third-party guarantee platform payment methods such as Alibaba. We promise to return and exchange the goods within 7 days of receipt so that you can buy with confidence and use them comfortably.

YOUR NEEDS, OUR HEARTBEAT

Quality determines survival,

service defines value!

CEO FENGMING YANG

Reviews

There are no reviews yet.