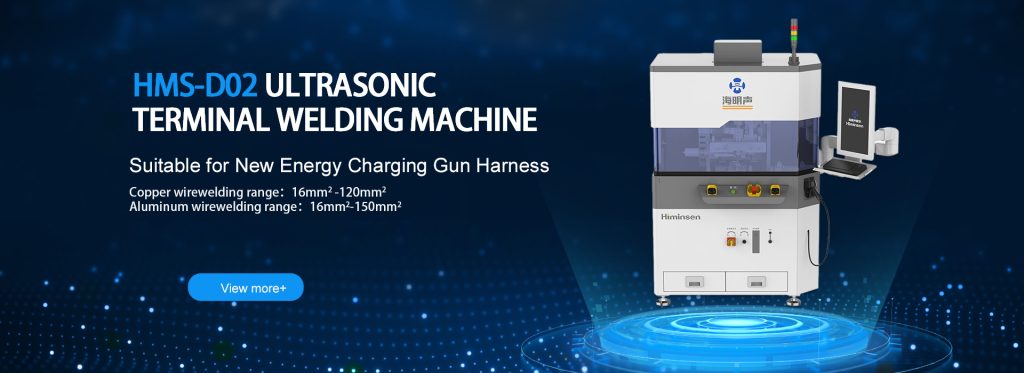

Equipment Introduction | HMS-D02G Ultrasonic Terminal Welding Machine

1.Equipment Introduction: The HMS-D02G ultrasonic terminal welding machine is a numerically controlled welding machine with a vertical structure. Its lifting adjustment meets ergonomic requirements. It adopts a four-cylinder and double solenoid valve control system...

Do You Know The Himinsen’s Main Products?

No 1:Ultrasonic terminal welding machine (HMS-D02G) The HMS-D02G ultrasonic terminal welding machine is a numerically controlled welding machine with a vertical structure. It is equipped with core components such as transducers, generators, amplitude transformers, and...

What is the core competitiveness of Guangdong Himinsen Technology Co., Ltd.?

The core competitiveness of Guangdong HiminsenTechnology Co., Ltd. is mainly reflected in the following aspects: 1. Technical research and development capabilities: -Deep technical accumulation: The company is developed on the basis of a core team with more than 20...

Himinsen & Haisheng sincerely invite you to visit | 2024 Shenzhen Charging and Swapping Power Exhibition CPSE.

The 7th Shenzhen International Charging Pile and Battery Swapping Station Exhibition will be held at the Shenzhen Convention and Exhibition Center from November 5th to 7th, 2024. It will focus on the innovative operation models and advanced equipment manufacturing...

Excellent Ultrasonic Wire Harness Welding Machine, Open the Road to High Efficiency!

This ultrasonic wire harness welding machine is easy to operate and has an astonishing welding speed. It can perfectly weld both automotive wire harnesses and electrical wire harnesses. With excellent quality and durability. Choosing it will inject strong power into...

“Ultrasonic Wire Harness Welding Machine, Accurately Connect the Future”

The brand-new ultrasonic wire harness welding machine is known for its high precision and stability. No solder is needed, which is environmentally friendly and highly efficient. It can quickly weld various wire harnesses and ensure a firm and reliable connection. It...

Grandly introduce an ultrasonic wire harness welding machine with extremely high cost performance!

The control system of the HMS-D01G features four cylinders and two solenoid valves, which can be monitored using an industrial touch display. Stable operation and high yield rate. All important components of the equipment are developed and produced in-house by...

How much do you know about the knowledge of ultrasonic wire harness welding?

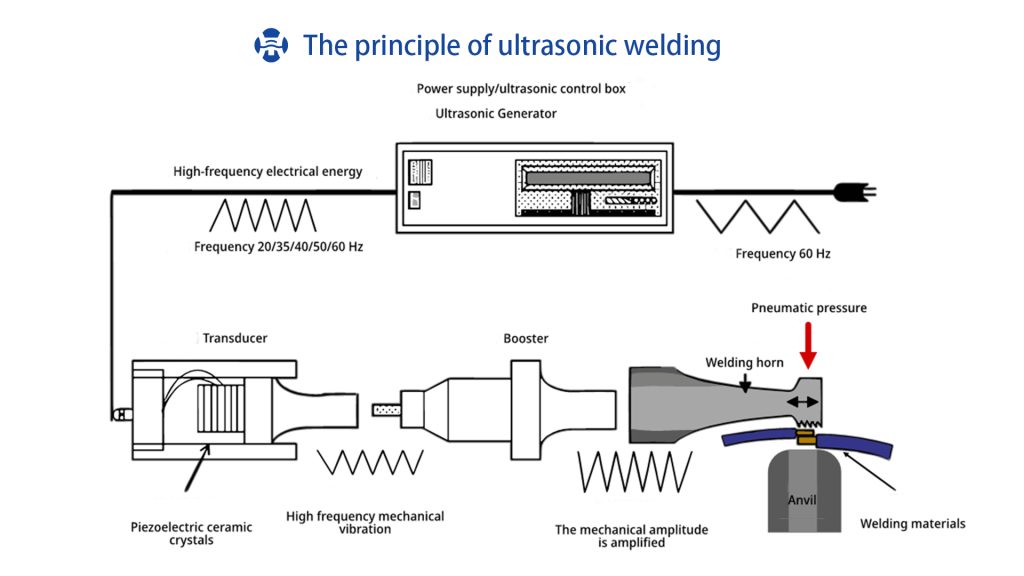

The principle of ultrasonic wire harness welding is as follows: Ultrasonic generators convert mains electricity into high-frequency and high-voltage alternating current and supply it to ultrasonic transducers. The transducer converts electrical energy into mechanical...

Do you know the working principle of the mute terminal crimping machine?

The working principles of mute terminal crimping machines mainly include the following two types: 1.Traditional method: In the past, ordinary terminal crimping machines usually adopted the stepping principle. That is, a motor drives a circuit breaker. Inside the...

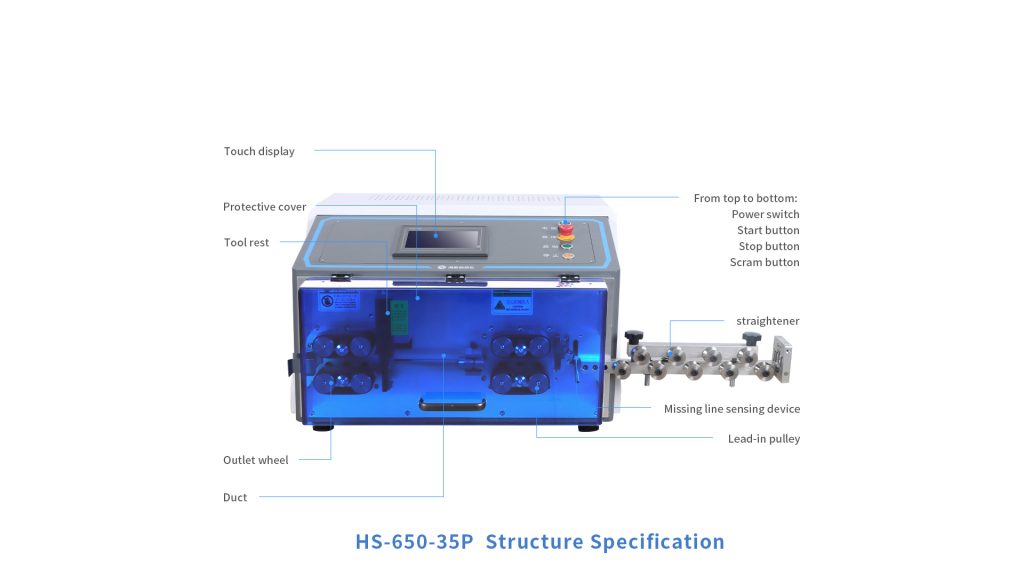

Let’s take a look the HS-650-35P Computer Wire Cutting and Stripping Machine together.

ModelHS-650-35PNumber of entering lineSingle lineSize560*520*450mm (excluding the protruding part of the straightener)Weight70kgDispaly method7-inch colorful PLC touch screenPower supplyAC220V 50/60HzPower650WPeeling lengthFront end 0-250mm, rear end 0-120mmApplicable...