In the development process of new energy vehicles, the development of battery capacity technology will be subject to certain constraints. The demand for alleviating mileage anxiety by pursuing vehicle lightweighting is constantly increasing, and the need to reduce the weight of vehicle wire harnesses has also become increasingly important. Currently, in the automotive wire harness industry, the plan to use aluminum wires instead of copper wires for wire harness lightweighting has become relatively mature. Some automobile manufacturers have already been using aluminum conductors on a large scale to transmit power energy. Compared with the original copper conductors, the use of aluminum conductors can achieve a weight reduction of about 40% and a cost savings of about 30%, which plays an important role in the development of vehicle weight reduction and cost reduction. Under the development trend of “replacing copper with aluminum”, aluminum conductors themselves are also constantly being improved. Due to the drawback of an increased diameter when using coaxial round conductors for replacement, in order to meet the current-carrying requirements for the entire vehicle’s electrical energy transmission, under the same current-carrying capacity, the outer diameter of aluminum conductors is approximately 1.3 times larger than that of copper conductors, resulting in insufficient layout space for the entire vehicle’s wire harnesses.

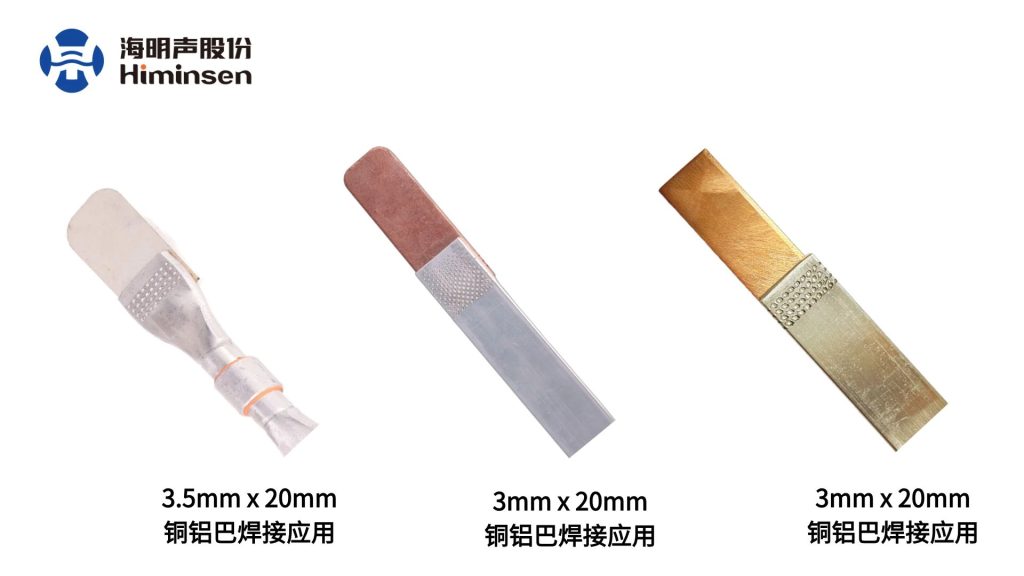

With its acute market insight and precise grasp of customer needs, Himinsen has replaced the original single-wire structure with conductive aluminum bars, thus solving the problem of weak electrical conductivity. Moreover, it has conducted in-depth research and development on the ultrasonic welding technology of conductive aluminum bars and has achieved great success in the market so far.

0 Comments