HIMINSEN’s fully automatic ultrasonic terminal welding machine ushers in a new journey of welding.

Are you still troubled by the inefficiency and low quality of traditional crimping methods? Haimingsheng’s new – generation ultrasonic terminal welding machine will lead you to experience an unprecedented welding experience!

In modern industrial production, ultrasonic welding technology is of utmost importance. However, traditional welding methods often suffer from problems such as low efficiency and unstable welding quality. Haimingsheng, well aware of these pain points, has made unremitting efforts and launched this fully automatic ultrasonic terminal welding machine!

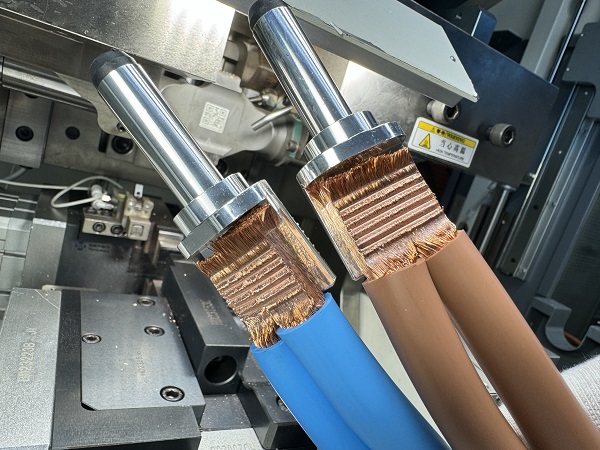

Haimingsheng’s new – generation ultrasonic terminal welding machine adopts advanced ultrasonic welding technology. It independently develops core components such as transducers, generators, horns, and welding heads, and has many advantages such as high efficiency, precision, and stability. It can achieve fully automated wire cutting, wire stripping, welding, and finished – product transportation, greatly improving production efficiency and welding quality.

Compared with traditional welding machines, Haimingsheng’s new – generation fully automatic ultrasonic terminal welding machine has achieved significant upgrades in the following aspects:

- Substantial Increase in Welding Speed

It adopts upgraded self – developed core components such as ultrasonic transducers, horns, generators, and welding heads. The welding speed is much faster than that of ordinary ultrasonic welding machines. With a power of 9000W, it can automatically perform single/double – end welding on copper/aluminum wires with a processing range of 6 – 95mm².

- Enhanced Welding Quality

By optimizing the welding process and parameters, the welded terminals are more firmly attached, more aesthetically pleasing, and have better electrical conductivity.

- Intelligent Operation

Equipped with a touch – screen intelligent industrial control computer control system, the operation is more convenient. With data monitoring, fully automated production can be achieved.

- Multifunctional Integration

In addition to the basic terminal harness welding function, it also has multiple functions such as fully automated wire cutting, wire stripping, welding, and finished – product transportation, meeting the needs of fully automated welding.

CONTACT US

EMAlL:delin@himinsens.com

TEL+8618938694287

ADDRESS: 101, BUILDING 8, JIN’AN BUILDING, SHANGCUN, GONGMING

STREET, GUANGMINGDISTRICT, SHENZHEN, GUANGDONG, CHINA

0 Comments