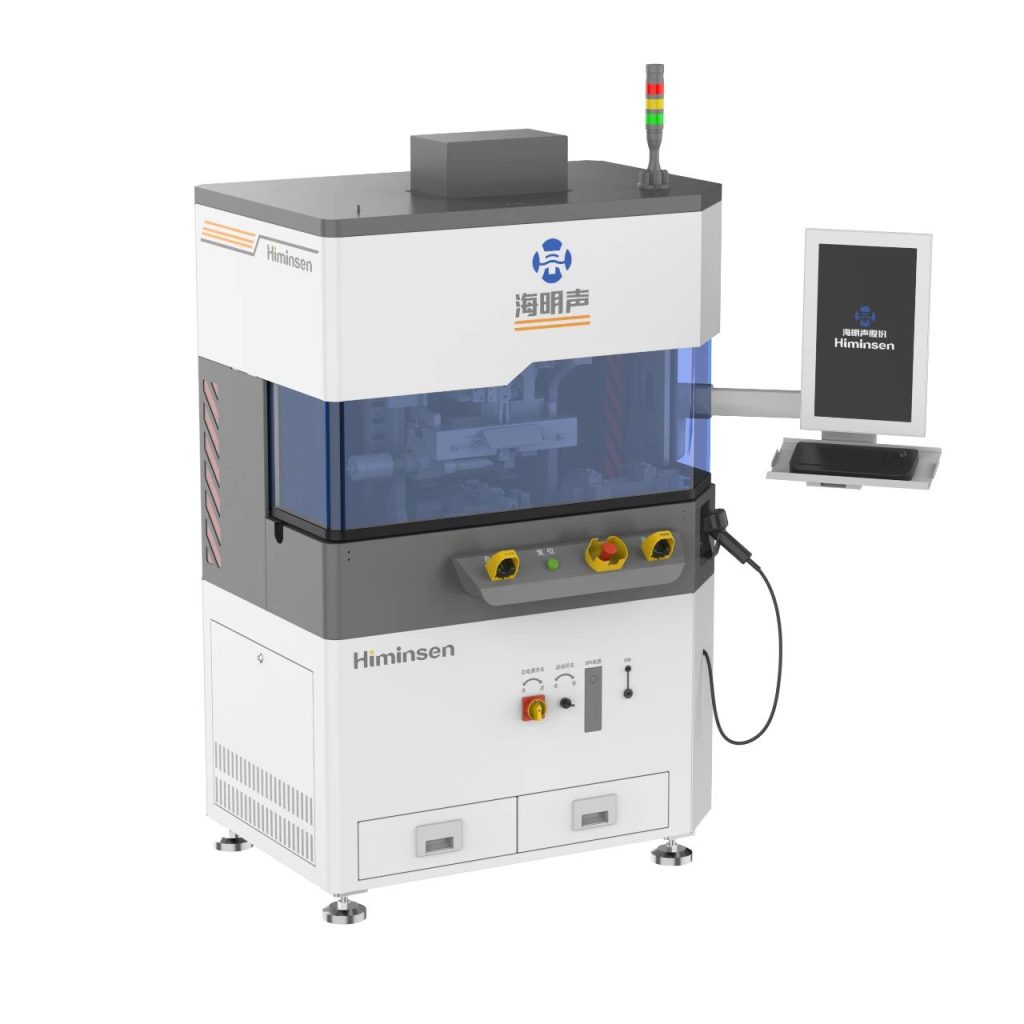

1.Equipment Introduction:

The HMS-D02G ultrasonic terminal welding machine is a numerically controlled welding machine with a vertical structure. Its lifting adjustment meets ergonomic requirements. It adopts a four-cylinder and double solenoid valve control system for stable operation. Equipped with an industrial touch screen, it is convenient to operate and the data is intuitive. The transducer, generator, horn, welding head, etc. independently developed by Himinsen greatly improve the performance of the whole machine. It is suitable for welding copper wires, tinned wires, aluminum wires and copper and aluminum terminals, and is widely used in new energy vehicle high-voltage wire harness connectors, new energy vehicle charging pile wire harness welding, etc.

2.Equipment Features

HMS – D02G ultrasonic terminal welding machine

1. Welding range: Welding of 16 ㎜² – 120 ㎜² copper cables and copper terminals; welding of 16 ㎜² – 150 ㎜² aluminum cables and copper terminals.

2. Welding materials: Welding of copper wires with silver – plated copper terminals, nickel – plated copper terminals, and bare copper terminals; welding of aluminum wires with silver – plated copper terminals, silver – plated aluminum terminals, and bare copper terminals.

3. Welding mode: 180° welding of cables and terminals.

4. Start – up mode: Start with both hands or start by scanning with a scanner gun.

5. On – line function: The MES system can identify and collect data such as the single – time welding output power, welding stroke, and welding time of the equipment.

6. Self – inspection function: The system automatically generates a quality monitoring file. It detects whether the single – time welded product meets the quality requirements for product welding through welding height, output power, welding time, welding energy, etc. In case of abnormality, an alarm will be triggered and the machine will stop.

Welding Sample

Welcome to contact us for more detail information.

0 Comments