No 1:Ultrasonic terminal welding machine (HMS-D02G)

The HMS-D02G ultrasonic terminal welding machine is a numerically controlled welding machine with a vertical structure. It is equipped with core components such as transducers, generators, amplitude transformers, and welding heads independently developed by Haimingsheng. The lifting adjustment meets ergonomic requirements. It adopts a four-cylinder and double solenoid valve control system, which is stable in operation. It is operated by an industrial touch display screen, and the data is intuitive. The HMS-D02G has a power of 13,000W. Welding range: 16-120 sqmm copper wires/tinned copper wires; 16-150 sqmm aluminum wires. It is widely used in welding of new energy vehicle charging guns, charging piles, high-voltage wire harness copper and aluminum terminals, etc.

No 2:Ultrasonic terminal welding machine (HMS-D01G)

The HMS-D01G ultrasonic terminal welding machine is a numerically controlled welding machine with a vertical structure. It is equipped with core components such as transducers, generators, amplitude transformers, and welding heads independently developed by Haimingsheng. The lifting adjustment meets ergonomic requirements. It adopts a four-cylinder and double solenoid valve control system, which is stable in operation. It is operated by an industrial touch display screen, and the data is intuitive. The HMS-D01G has a power of 9,000W. Welding range: 6-95 sqmm copper wires/tinned copper wires; 6-95 sqmm aluminum wires. It is widely used in welding of new energy vehicle charging guns, charging piles, high-voltage wire harness copper and aluminum terminals, etc.

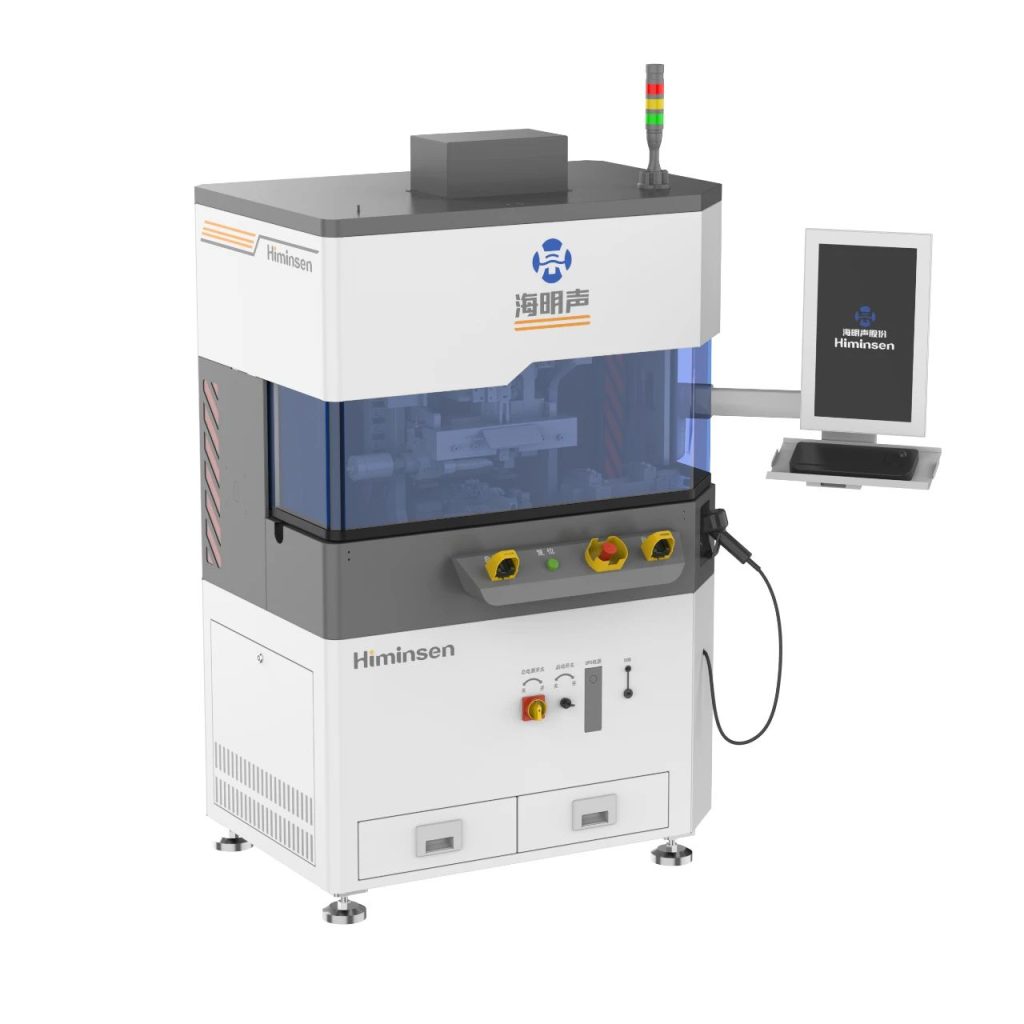

No 3:Ultrasonic terminal welding machine (HMS-D01Z)

HMS-D01Z, Himinsen’s fully automatic ultrasonic terminal welding machine has a desktop structure with an integrated design of the chassis and the frame. The equipment’s lifting adjustment is lightweight. The replacement of ultrasonic core components is simple and quick. The transmission mechanism operates smoothly. It is operated by an industrial touch display screen with intuitive data and convenient operation. The independently developed core accessories by Haimingsheng greatly enhance the overall performance of the machine. With a power of 9,000W, it can perform automatic single-ended and double-ended welding for copper/aluminum wires in the range of 6-95 sqmm millimeters.

No 4:Ultrasonic wire harness welding machine (HMS-D00)

The HMS-D00 ultrasonic terminal welding machine is a semi-automatic metal welding machine with a desktop structure. It is equipped with core components such as transducers, generators, amplitude transformers, and welding heads independently developed by Haimingsheng. It operates stably and is operated by an industrial touch display screen with intuitive data. The HMS-D00 has a power of 4,000W. Welding range: 2.5-25 sqmm copper wires/tinned copper wires; 2.5-35 sqmm aluminum wires. It is mainly used for AC gun welding.

For more information, please contact us.

0 Comments