With the rapid development of the automotive electronics and new energy industries, the quality and efficiency of wire harness welding have become crucial for enterprise competition. Traditional welding processes often suffer from problems such as poor soldering, oxidation, and deformation, which not only affect product performance but also increase costs and delivery cycles. Himinsen, with its cutting – edge ultrasonic wire harness welding technology, provides efficient sampling services for numerous enterprises, successfully tackling industry challenges!

Case : Welding of Core Components in New Energy Vehicles

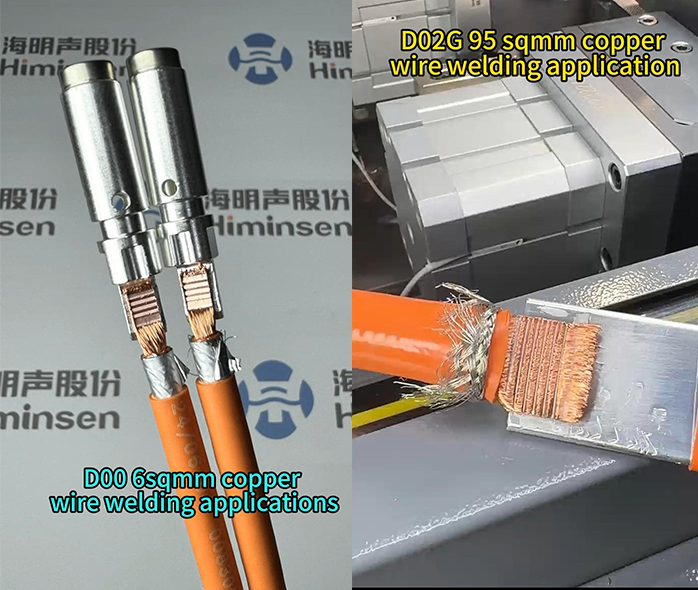

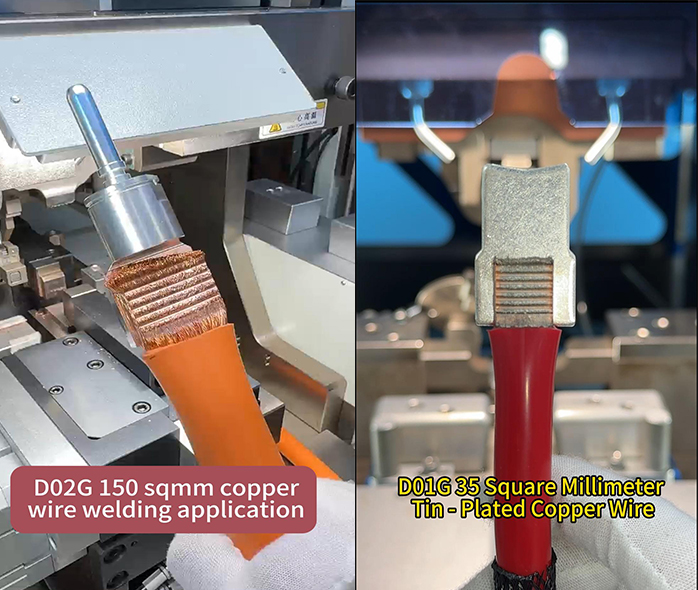

When a leading new energy vehicle manufacturer was developing a new – generation battery management system, it needed to weld multiple copper wires of different specifications to precision terminals. Traditional welding methods caused wire fusing and terminal deformation, failing to meet safety standards. Our team conducted in – depth analysis of the product requirements and used Himinsen’s customized ultrasonic wire harness welding equipment

If you need to inquire about more detailed information, please contact the contact details below.

CONTACT US

EMAlL:delin@himinsens.com

TEL+8618938694287

ADDRESS: 101, BUILDING 8, JIN’AN BUILDING, SHANGCUN, GONGMING

STREET, GUANGMINGDISTRICT, SHENZHEN, GUANGDONG, CHINA

24/7 Live Chat

Global customer service center, 24 hours online to provide you with pre-sales and after-sales consulting services.

Fast Delivery

A comprehensive supply chain management system, smart production system for products, and quality control management system ensure rapid delivery within 30 days.

Secure Checkout

We support T/T and also support international third-party guarantee platform payment methods such as Alibaba. We promise to return and exchange the goods within 7 days of receipt so that you can buy with confidence and use them comfortably.

YOUR NEEDS, OUR HEARTBEAT

Quality determines survival,

service defines value!

CEO FENGMING YANG