The advantages of ultrasonic wire harness welding are as follows:

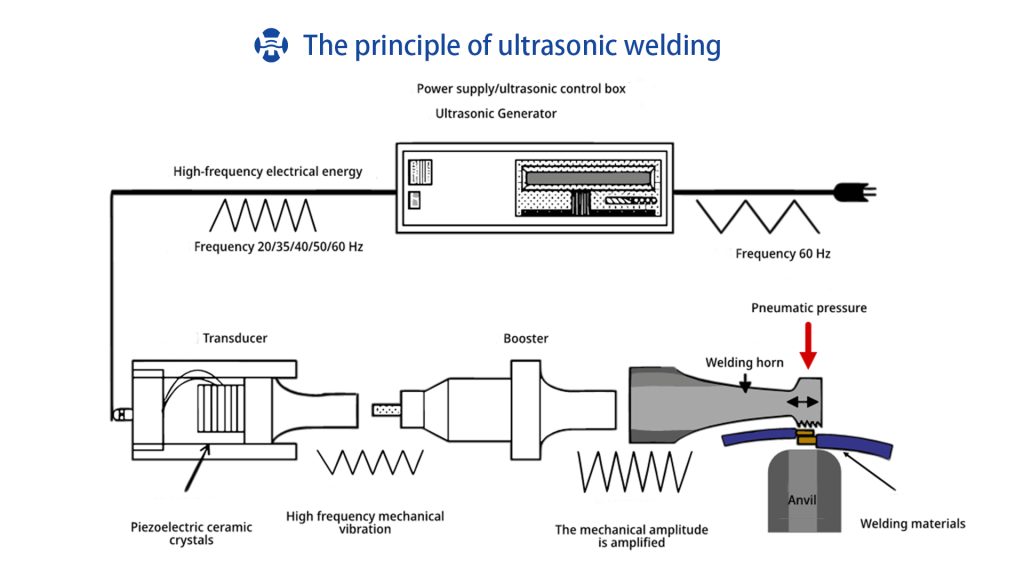

1. High welding quality: Through high-frequency vibration, the metal surfaces rub against each other to remove the oxide layer and achieve bonding at the molecular level. The welded joint has high strength and good electrical conductivity, ensuring the reliability and stability of the wire harness connection.

2. Minimal damage to materials: No soldering flux is required during the welding process, and there is no situation of high-temperature melting of the metal. Therefore, it has little impact on the material properties of the wires and terminals, and can avoid problems such as material overheating, deformation, and embrittlement. It is especially suitable for materials that are sensitive to temperature.

3. High welding efficiency: The welding time is short, usually only a few seconds are needed to complete one welding point. Moreover, multiple wire harnesses can be welded simultaneously, which can effectively improve production efficiency and is suitable for large-scale automated production.

4. Environmental protection and energy conservation: Ultrasonic welding is a physical welding method that does not generate pollutants such as smoke and exhaust gas, nor does it consume a large amount of energy, meeting the requirements of environmental protection and energy conservation.

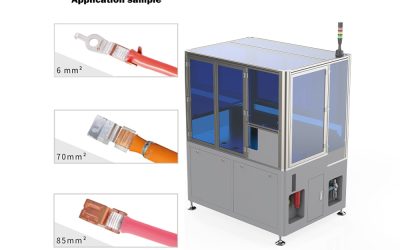

5. Strong adaptability: It can weld metal wire harnesses made of various different materials, such as copper, aluminum and their alloys, etc. It can also meet the welding requirements of wire harnesses with different specifications and shapes. Whether it is a thin wire harness or a thick wire harness, a good welding effect can be achieved.

6. High degree of automation: It is easy to integrate with automated production lines. The welding parameters and welding positions can be precisely controlled through programming, reducing errors in manual operation and improving the consistency of product quality. 7. High safety: No open fire or high temperature is generated during the welding process, reducing potential safety hazards such as fires and scalds, and the operation is relatively safe.

If you need to inquire about more detailed information, please contact the contact details below.

CONTACT US

EMAlL:delin@himinsens.com

TEL+8618938694287

ADDRESS: 101, BUILDING 8, JIN’AN BUILDING, SHANGCUN, GONGMING

STREET, GUANGMINGDISTRICT, SHENZHEN, GUANGDONG, CHINA

0 Comments